Wiązary hal

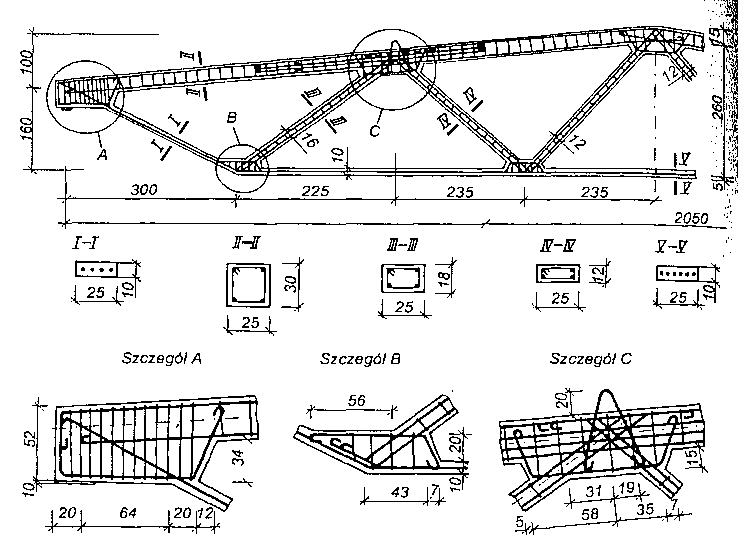

Wiązary żelbetowe oraz segmenty składowe wykonywane są w pozycji leżącej (poziomej), w związku z czym przekroje pasów oraz słupków i ców mają zwykle kształt kwadratu lub prostokąta. Na rysunku przedstawiono zbrojenie jednosegmentowego dźwigara żelbetowego. Istotną sprawą są prawidłowe połączenie zbrojenia i jego zakotwienie w węzłach.

Wiązary żelbetowe oraz segmenty składowe wykonywane są w pozycji leżącej (poziomej), w związku z czym przekroje pasów oraz słupków i ców mają zwykle kształt kwadratu lub prostokąta. Na rysunku przedstawiono zbrojenie jednosegmentowego dźwigara żelbetowego. Istotną sprawą są prawidłowe połączenie zbrojenia i jego zakotwienie w węzłach.

Na pasach górnych wiązarów układane są płyty dachowe. W niektórych rozwiązaniach dachów płyty te połączone są betonem ze sobą i pasem. Dla lepszego połączenia (zmonolicenia) płyt z dźwigarem wypuszcza się strzemiona z pasa dźwigara.

Wiązary o większych rozpiętościach opiera się na słupach lub ścianach za pośrednictwem łożysk, które najczęściej stanowią blachy stalowe o grubości 6-10 mm.

Podobnie do wiązarów kratowych, istnieje również wiele odmian dźwigarów belkowych. Na przekrycia hal stosowane są dźwigary o stałej wysokości, ze spadkami lub łukowe. Spadki połaci dachowej przy stosowaniu dźwigarów o stałej wysokości uzyskuje się przez stosowanie słupów o różnej wysokości.

Sztywność hal na działanie poziomych sił zapewniają w kierunku poprzecznym słupy zamocowane w fundamentach. Słupy te są przeważnie jednogałęziowe o przekroju prostokątnym, ale mogą być też dwugałęziowe. Ustawione są one większym wymiarem boku w kierunku poprzecznym a mniejszym w kierunku podłużnym budynku.

Sztywność słupów może być niewystarczająca do zapewnienia stateczności hali w kierunku podłużnym, szczególnie wtedy, gdy rozpiętość hali i jej wysokość są duże. W tym przypadku do współpracy że słupami mogą być włączone zewnętrzne ściany podłużne, jeśli nie są one ścianami lekkimi typu osłonowego. W przypadku hal ze ścianami lekkimi (osłonowymi) usztywnienie w kierunku podłużnym można zapewnić przez zastosowanie tężników umieszczonych w skrajnych polach.

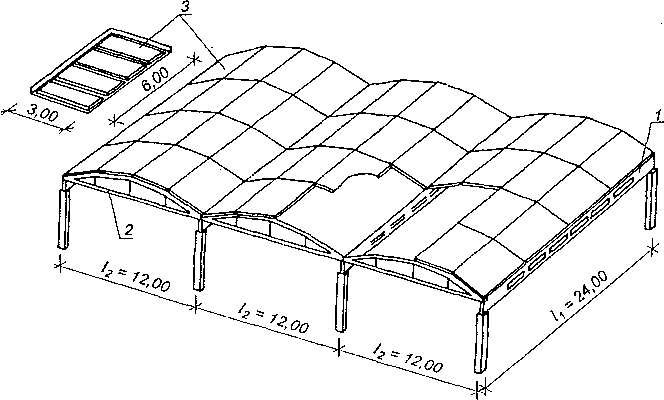

Powłoka walcowa prefabrykowana o siatce słupów 12×24 m; 1 — belka brzegowa (wezgłowiowa), 2 — przepona, 3 — płyta.

Powłoka walcowa prefabrykowana o siatce słupów 12×24 m; 1 — belka brzegowa (wezgłowiowa), 2 — przepona, 3 — płyta.

Z elementów prefabrykowanych można również wykonać przekrycia powłokowe jedno- i dwukrzywiznowe. Na rysunku pokazano powłokę walcową jednokrzywiznową. Rozstaw przepon jest długością (rozpiętością) powłoki, natomiast rozstaw belek brzegowych (wezgłowiowych) l2 – szerokością powłoki. Powłoka utworzona jest z płyt prefabrykowanych o wymiarach 300 x 600 cm zmonoliconych na miejscu budowy.